Low-carbon concrete in the UAE: from idea to specification

Low-carbon concrete has moved from a niche sustainability topic to a core part of how projects are assessed, funded and approved. For the UAE, where concrete underpins almost every building and piece of infrastructure, it is one of the biggest levers for reducing embodied carbon without changing typology or programme.

ARDH Collective’s answer to this challenge is DuneCrete, a low-carbon concrete based on desert sand, designed specifically for this region. This overview is written for architects, developers and engineers who want low-carbon concrete they can actually specify and build with in the UAE.

What “low-carbon concrete” should mean

At ARDH, the term “low-carbon concrete” is only useful if a mix does all of the following:

Lower cement content

• Uses less clinker-based Portland cement per cubic metre than a standard reference mix for the same application.

• Achieves the required strength and durability with a more efficient binder system.

Smarter materials

• Incorporates supplementary or alternative materials in the binder and aggregate system wherever appropriate.

• Makes use of local resources, including desert sand, instead of relying only on imported aggregates.

Measurable embodied-carbon reduction

• Delivers a clear reduction in embodied carbon per cubic metre compared with a typical regional mix.

• Treats “low-carbon” as a performance outcome, not just a marketing label.

This is the standard we apply to DuneCrete and the lens we recommend for any low-carbon concrete option.

Why low-carbon concrete matters in the UAE

The UAE continues to build at scale. Every new tower, villa, infrastructure link and public realm project locks in embodied carbon for decades. Because concrete volumes are so high, even modest improvements in the mix can have a significant impact.

Bringing low-carbon concrete into UAE projects:

- • Reduces emissions where material volume is highest – structure, slabs, foundations and external works.

• Supports climate and sustainability targets by addressing materials, not just operational energy.

• Opens the door for regional solutions that use local resources, rather than importing answers from elsewhere.

For project teams, low-carbon concrete is one of the most direct ways to align design and construction with long-term decarbonisation goals.

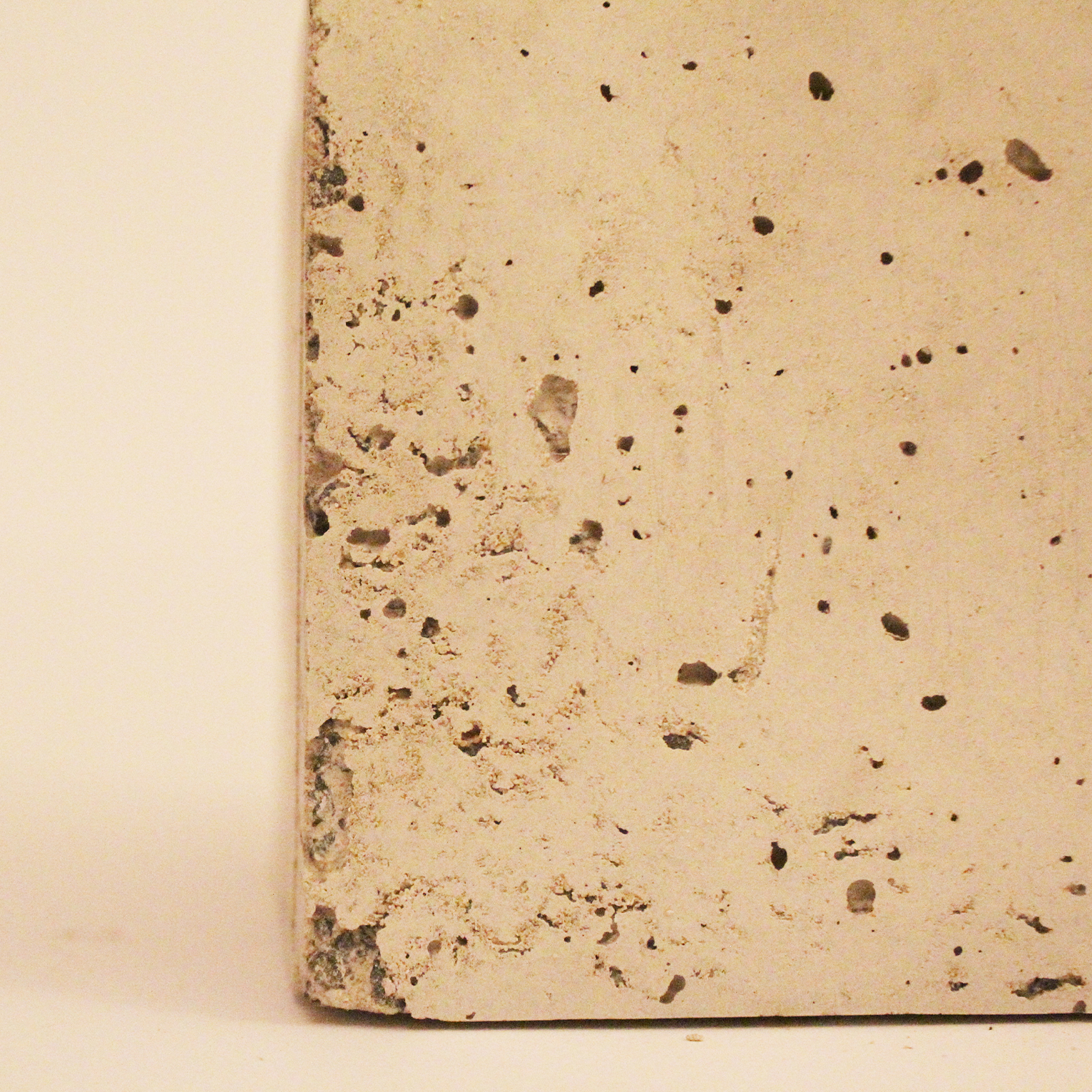

DuneCrete: desert-sand-based low-carbon concrete. DuneCrete is ARDH’s low-carbon concrete developed around UAE desert sand rather than imported or riverbed aggregates.

DuneCrete is ARDH’s desert-sand-based low-carbon concrete:

- • Uses carefully graded desert sand as a major component, reducing reliance on imported river sand.

• Optimises the mix to lower cement content while maintaining required performance for defined uses.

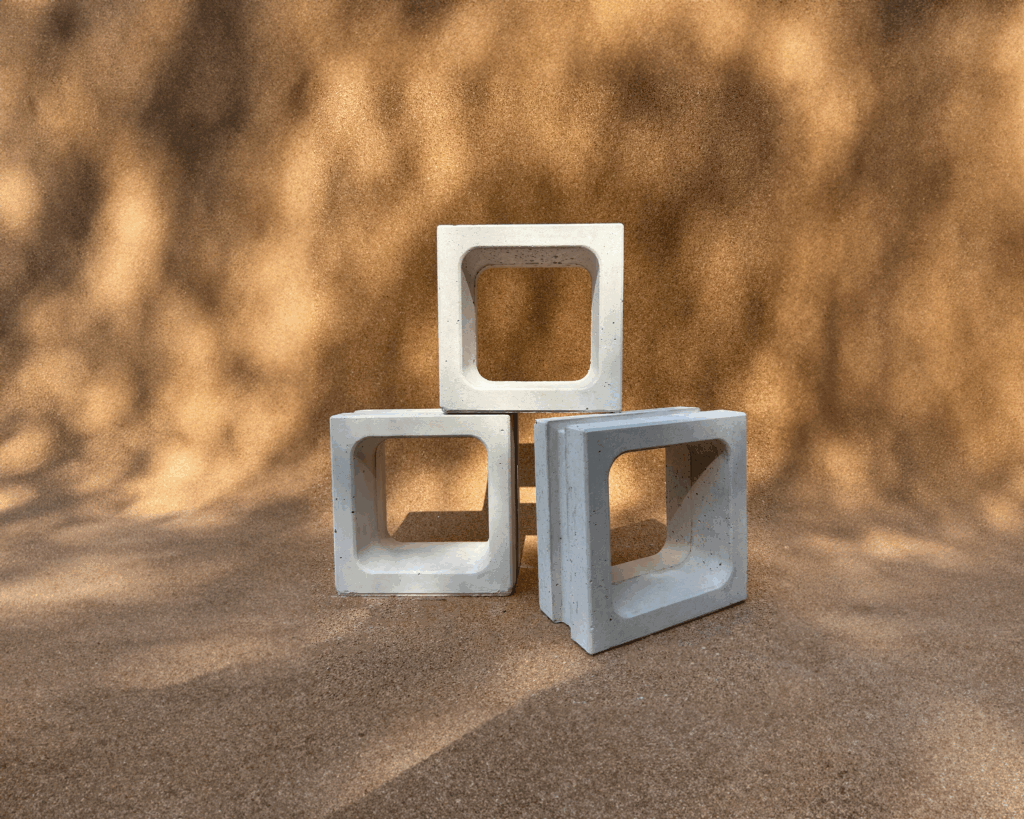

• Can be used as a cast mix, a 3D-printable mix, and as the base for DuneBlocks breeze / claustra units.

The result is a concrete that behaves like concrete, fits into familiar workflows on site and carries a significantly lower embodied-carbon profile than typical mixes in the region.

Where it fits in UAE projects

- • Public realm and landscape elements – benches, seating blocks, plinths, planters, low walls and steps.

• Façade screens and boundary walls using DuneBlocks, where shade, privacy and airflow are key.

• Selected structural or semi-structural elements, depending on engineering design and exposure conditions.

Rather than trying to replace every cubic metre at once, project teams can target these elements first to move meaningful volumes into a low-carbon mix.

How to specify DuneCrete in a UAE project. Bringing DuneCrete into a project is most effective when it is considered early and written clearly into the specification.

Map concrete use across the project

• Identify where concrete volumes are highest.

• Highlight repetitive or non-special elements as early candidates for substitution.

Review data with structural and sustainability teams

• Request DuneCrete technical data sheets and indicative embodied-carbon figures.

• Review them alongside structural requirements, durability needs and project ESG or certification targets.

Write DuneCrete into specifications and BOQs

• Name DuneCrete explicitly for the selected elements, rather than leaving it as a generic option.

• Include required strength classes, exposure conditions and surface expectations.

Capture the benefit.

• Record the shift from a standard reference mix to DuneCrete in project documentation.

• Use the embodied-carbon reduction as part of the project narrative to clients, investors and regulators.

How ARDH can support your next project

For teams considering low-carbon concrete in the UAE, ARDH can provide:

- • DuneCrete technical data and indicative embodied-carbon figures.

• Guidance on suitable applications and detailing, including where DuneBlocks breeze blocks are a good fit.

• Support in early design and specification, so low-carbon concrete is built into the project rather than added as a late change.

DuneCrete is designed to make low-carbon concrete a practical, repeatable material choice for UAE and GCC projects, not an experiment.